Everything you need to know about springs

Knowledge centerDoor springs are a crucial part of sectional garage doors. Our wide range of springs include solutions for every situation: from large industrial door systems to residential garage doors with limited build in space. In this article, we'll explain the different types of springs, their unique features, and their benefits.

Torsion springs

Torsion springs work by twisting around a shaft. As the door system closes, the spring winds up and stores energy and as the door opens, the spring unwinds and helps lift the door.

Spring related tools

Spring winding tools and a wire gauge make installing and replacing springs easier

Extension springs

Extension springs stretch along the vertical angle when the door closes and contract when it opens.

Spring configurators

Find the correct spring for you door system based on your dimensions and desired lifecycle

Become a partner

Are you interested in partnering with DOCO and do you want full access to our webshop, configurators and more? Contact us now and plan your visit or online meeting. Plan your meeting nowFeatures

Introduction of Sectional Door Springs

Springs are used to counterbalance the weight of the door leaf when opening or closing an overhead door. They are a crucial component that esentially stores and releases energy to lift the door leaf. Without a spring, the full weight must be lifted by the user or the garage door operator.

We distinguish two types of springs: extension springs, which provide tension by stretching and contracting, and torsion springs, which apply torque through winding and unwinding. Both types serve the same purpose of balancing the door’s weight, but there is a difference in installation requirements which we will explain more in this article.

We can offer you both types of springs, and more. Our residential door system HOME-X can be ordered with pre-tensioned extension springs. For torsion springs we also have two high-end spring winding tools: Surewinder and Brutewinder.

Residential door systems: Extension or Torsion springs?

When selecting a garage door system, understanding the difference between extension springs and torsion springs is essential in terms of weight and available space.

Extension spring systems, like the HOME-X, are easy to install and perfect for garage doors where space is limited. It requires only 90 mm of headroom without a garage door operator and 120 mm with a garage door operator, making it ideal for a garages with low ceilings. The HOME-X system supports a maximum door weight of 130 kg, which makes it perfect for smaller or lighter garage doors.

Torsion spring systems, such as HOME-F (with torsion springs in the front) and HOME-R (with torsion springs in the rear), offer significantly greater lifting power. HOME-F can handle up to 295 kg, making it suitable for heavy residential garage doors. HOME-R supports up to 165 kg and is a compromise between maximum door weights and build-in space. Both torsion systems require 85 mm of side space, which is the same as the extension spring model, but more headroom (190 mm for HOME-F and at least 90 mm for HOME-R).

Ultimately, the choice between extension springs or torsion springs depends on both the weight of the garage door the available build-in space. Torsion springs provide more lifting capacity, while extension springs are much easier to install.

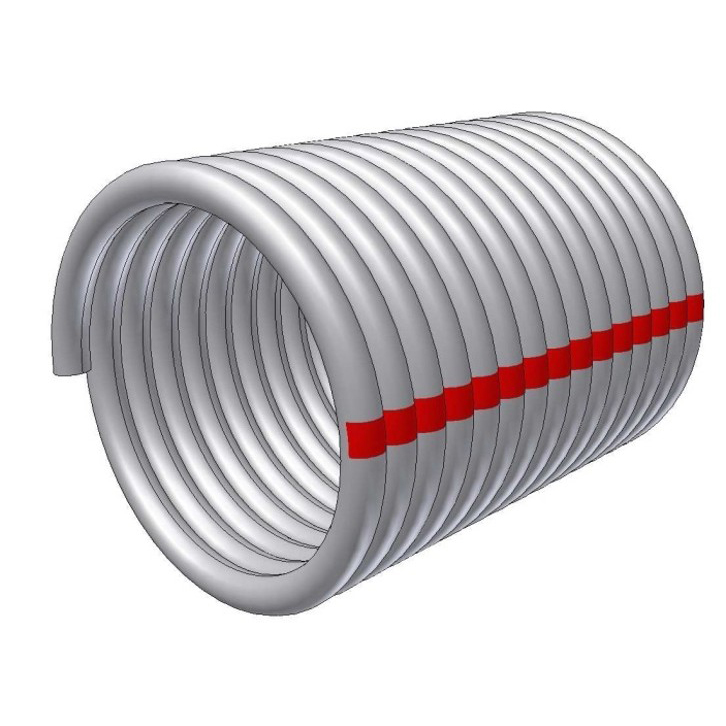

Extension Springs

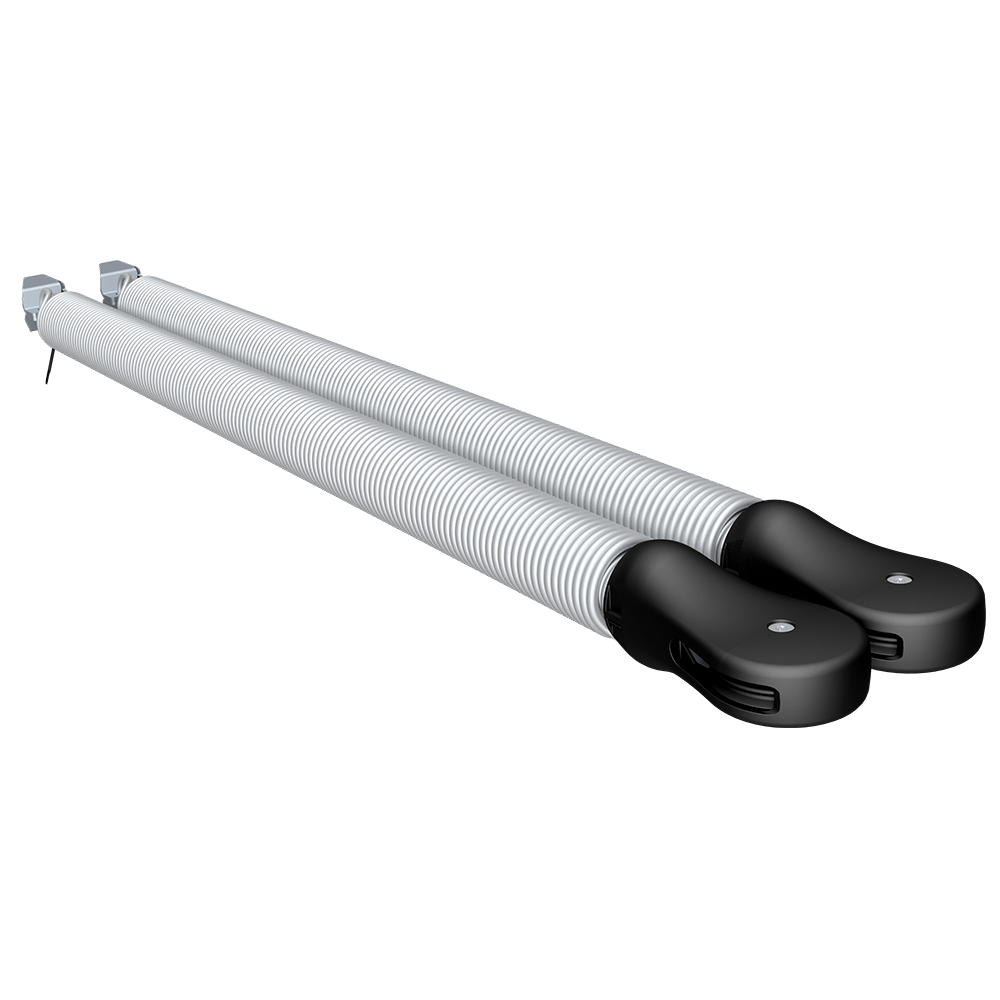

System: HOME-X

Our extension springs are designed to deliver optimal performance, always consisting of multiple concentric springs. Each spring includes a mounting hook for easy attachment to the vertical angle. At the top, an integrated cable pulley is covered with a black cover for a professional look.

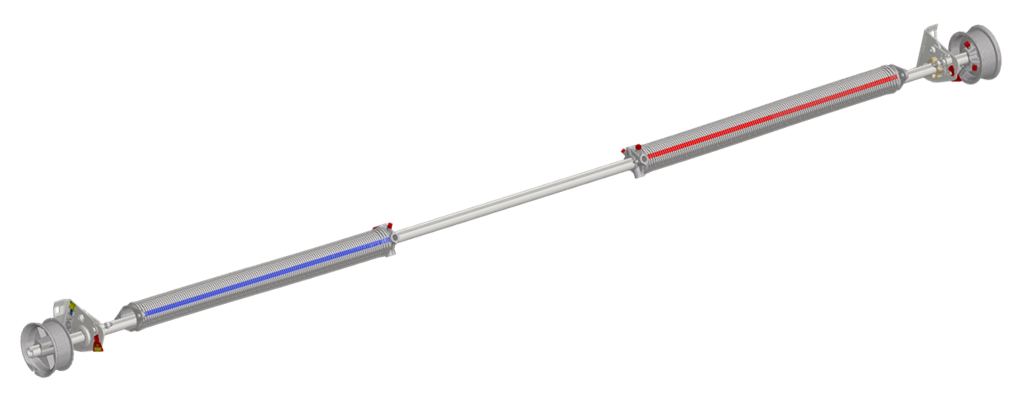

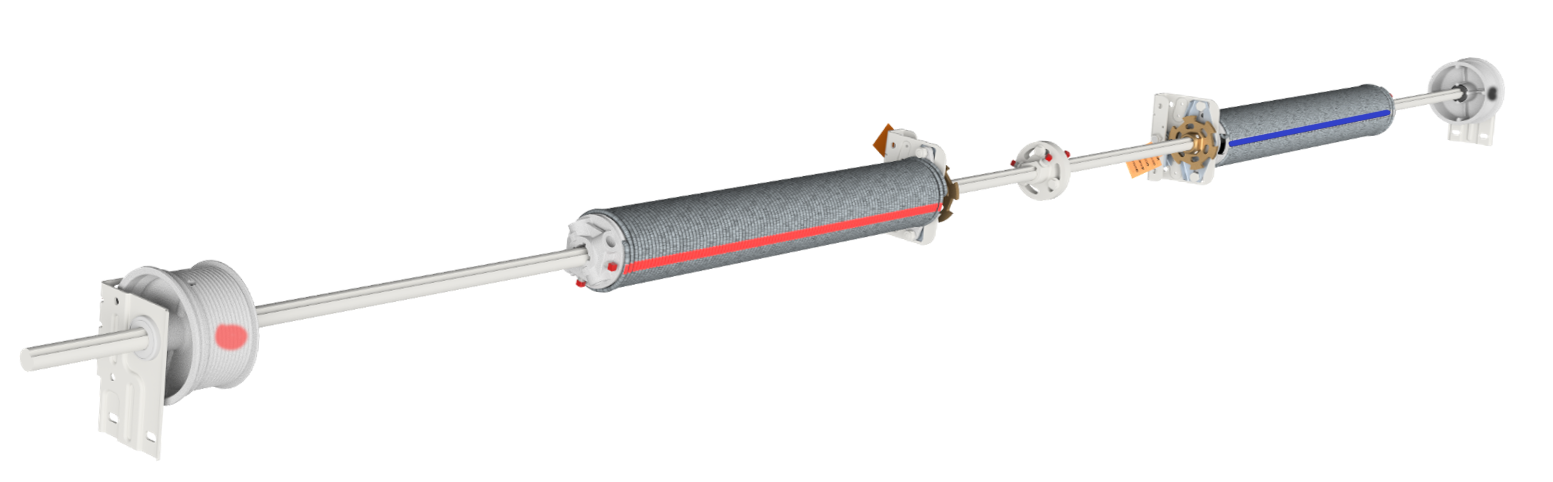

Pre-Assembled Torsion Springs

System: HOME-F, HOME-R

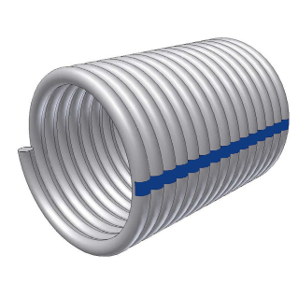

Our torsion springs for residential door systems come pre-assembled. Each spring is color marked, making it easy to distinguish left winding springs and right winding springs.

Industrial torsion springs: Shot blasted, galvanized or black?

The surface finish plays a key role in how well a spring performs in specific environments and how long it lasts. Cost-efficiency, resistance to weather conditions, or extended service life, understanding the differences between spring finishes helps you choose the right spring.

We compare three types of industrial torsion springs and highlighting their strengths, limitations, and typical use cases.

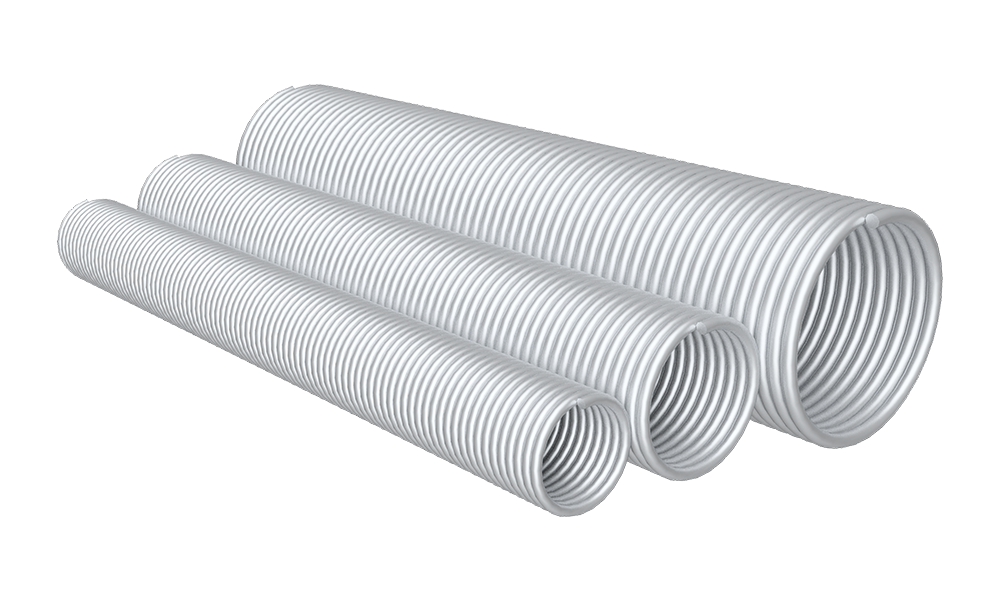

Shot blasted springs

Shot blasted springs are DOCO’s standard choice for industrial torsion springs. They enable the use of lighter or smaller springs for the same application compared to other spring types. Additional coating adds an extra layer of protection, increasing the longevity. Shot blasted springs provide a cost-effective solution with a longer lifecycle compared to black or galvanized springs of equal size.

Galvanized springs

Galvanized springs offer better resistance to corrosion compared to black springs, making them perfect for use in marine environments. These springs are made to order ensuring a tailored solution for your needs.

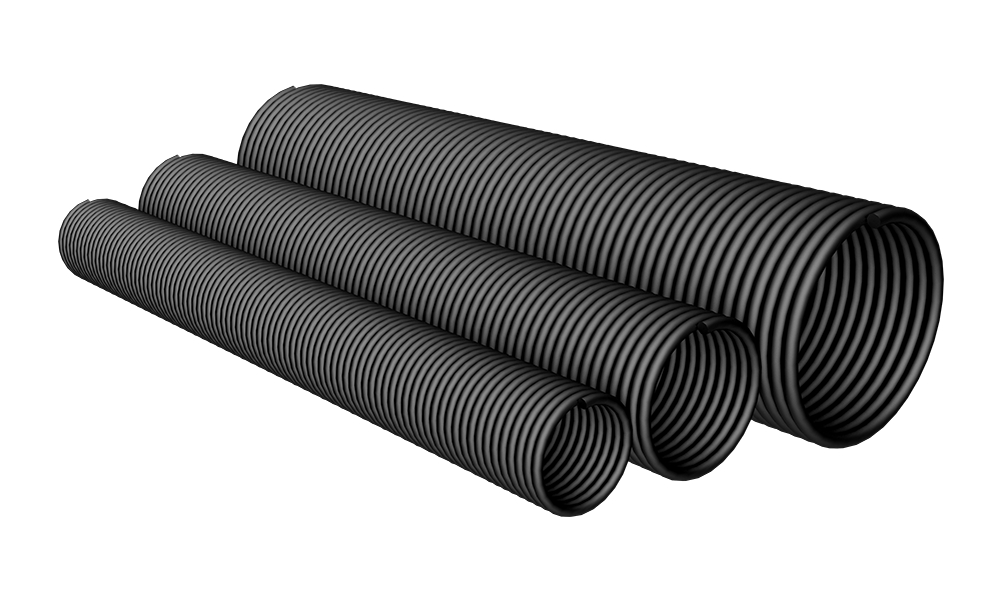

Black springs

Black springs are our most cost-effective option, making them a good choice for projects where budget is important. Like galvanized springs, black springs are made to order and are not available in stock.

Torsion springs: Color markings and their position on the power-unit

The colors represent the winding direction

As you may have noticed the words left and right, when refering to the name of a spring refer to the winding direction of the torsion spring. A left winding spring rotates counterclockwise, a right winding spring rotates clockwise. Note that it's not the position of the springs on the power-unit, since they are placed differtly on residential garage doors compared to industrial garage doors.

Blue or Black: Left winding spring

Red: Right winding spring

Spring position on residential door systems

On residential garage doors the left winding spring is mounted on the left side of the power-unit and the right winding spring on the right side. The stationary spring plug is mounted on the spring break device facing the end of the shaft and the winding plug is placed towards the center of the shaft.

Spring position on industrial door systems

On industrial door systems the left winding spring is mounted on the right side of the power-unit, the right winding spring on the left side. The stationary spring plug is mounted on the spring break device towards the center of the shaft and the winding plug is placed facing the end of the shaft. Industrial cable drums and springs typically have matching color indicators, meaning that the red spring is mounted on the side of the red drum and the blue or black spring is mounted on the side of the black drum.

How to determine the wire thickness?

Method 1: With our spring wire gauge

Hold the comb on the unwound spring. There is only 1 size that fits perfectly and indicates the exact wire size.

Method 2: With a tape measure

Count and measure 10 coils of the unwound spring. Divide the length by 10 to get the wire thickness.

Spring wire gauge

900125

Measuring tool suitable for measuring the wire thickness of a torsion spring. The ideal tool when you are replacing springs.

Suitable for the following wire thicknesses: 4.5 - 5.0 - 5.5 - 6.0 - 6.5 - 7.0 - 7.5 - 8.0 - 8.5 - 9.0 - 9.5 - 10 - 10.5 - 11 - 11.5

DOCO spring calculators

To make selecting the correct garage door springs easy, we have two spring calculators. Each tool is designed to help you calculate the optimal springs (and the best alternatives) based on your requirements. You only need to input a few details about your door to calculate the springs.

Note that the door width does not affect the required spring force, but is used to calculate if there is enough space for the springs to be mounted.

- Door height and width

- Door leaf weight: The combined weight of panels, hinges, aluminum profiles, strengthening profiles, seals, end caps, and other components attached to the panels

- Cable drums: Type and diameter of the cable drums

- Desired spring lifecycle (optional for torsion springs): For torsion springs we always start at 15,000 cycles or more, but this can be increased if desired

Find the right spring for you garage door

We have two different calculators, one for residential door systems with extension springs or torsion springs and one for torsion springs used in industrial garage doors. They are both available on our support page.

Go to spring calculatorsCustom-made springs for service and replacement

In addition to our standard spring range, we offer the option to order custom-made springs. This service is especially useful when servicing broken springs in existing garage doors, where no standard replacement is available.

This flexibility ensures that all dor systems can be serviced. You can specify every detail such as; inner diameter, length, wire thickness, winding direction (left or right), spring type (shot blasted, galvanized, or black).

Custom-made springs are typically delivered within 2 to 3 weeks and we also offer an express 24-hour service.

Guaranteed quality thanks to in house testing

Our R&D test center plays a crucial role in testing the quality and durability of all our products, including our springs.

Our springs undergo continuous testing as we simulate opening and closing a garage door until a spring fails. We gather data on performance, durability, and lifespan and this process helps us verify that our springs meet the required standards.

The springs resulting from our spring calculators, always exceed 15.000 cycles for torsion springs while the lifecycle of our extension springs is based on our spring matrix. For torsion springs you can manually change this value in our spring calculator to an even higher value.

Pre-tensioned Extension Springs

Extension springs can be pre-tensioned and mounted into the vertical angle, streamlining the installation process of a HOME-X.

Our pre-tensioned extension springs simplify the installation of HOME-X residential doors, requiring just 10-15% of the door’s weight of up to 130 kg to be lifted by the installer. This makes single-person installation very easy.

You can read more about our pre-tensioned extension springs in our knowledge base.

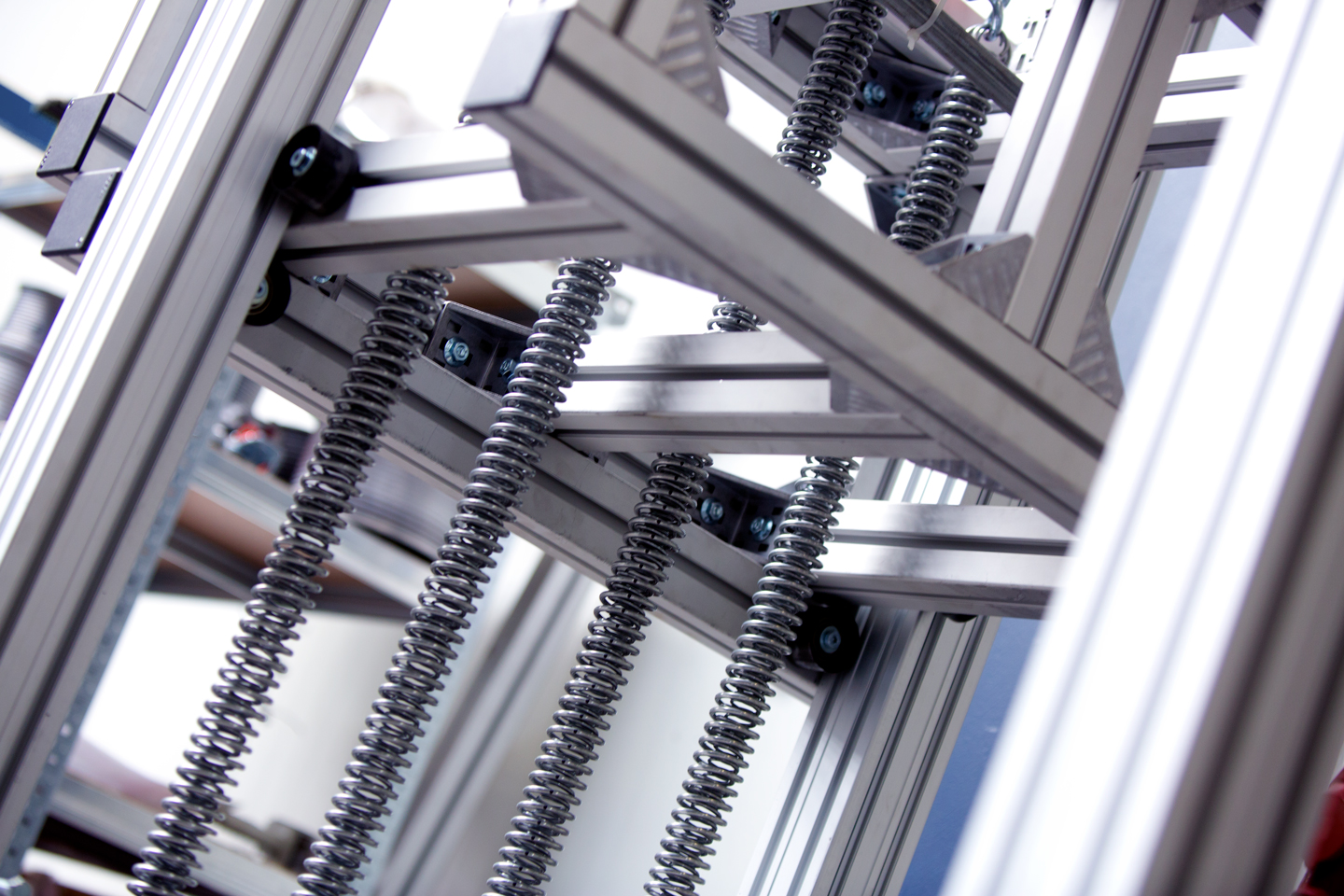

Our Spring Winding Tools

At DOCO, we have two high-quality, robust spring winding tools in our assortment: the Surewinder and the Brutewinder.

Our spring winding tools are designed to improve safety and efficiency in your work. The tool does the heavy lifting, providing a more ergonomic experience compared to traditional winding bars.

Unlike heavier alternatives, our tools are remarkably lightweight without compromising power, making them easier to handle and reducing strain during use.

Interested in our garage door springs?

Become a DOCO partner and gain full access to our webshop, configurators, spring calculators, and more. From pre-assembled torsion springs to custom-made replacements and many more components, we’ve got the complete solution for every garage door system, residential or industrial.

Contact us for a visitHow can we help?

Would you like to know more about how our products and services can help you? Please contact us.